Mention Hydro-lectric system to anyone who even knows what they are and you’ll get mixed reactions; mostly negative. It’s not that these systems didn’t work well; in fact, I’ve seen some that work as well, if not better, than a “modern” system! The problem(s) arise from lack of proper maintenance, long periods of storage, or a combination. My first experience with Hydro-lectric systems was in 1989 when I undertook the restoration of a very rough 1948 Cadillac convertible. The entire system on the car needed rebuilding, as the vehicle had been in storage for many years and time took its toll. After many hours of labor, an endless litany of expletives I can’t repeat here, and a serious cash outlay, I found, much to my astonishment and satisfaction that everything actually worked! In fact, the gentleman who bought the car in 1990 reports that the system still performs flawlessly!

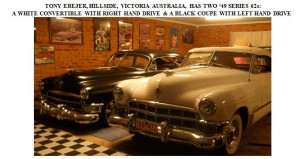

Cadillac, various other GM makes, and other car manufacturers had been using the Hydro-lectric system since the early 1940s. At least in 1949, which I’m most familiar with, the system was standard equipment on the 60 Special, convertible, Coupe De Ville, and some models in the 75 series. It was an extra-cost option on the Series 62 sedans and coupes, but since it was rather “pricey” at $121.65, few Series 62 buyers opted for it. The system was used until 1953, when electric power windows appeared on all vehicles.

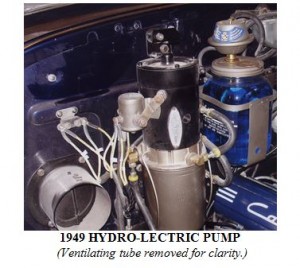

The Hydro-lectric system was revolutionary when it was introduced, and a veritable marvel of engineering, especially considering it was designed and executed way before the days of CAD (Computer Assisted Drafting). It’s also an extremely ingenious system that with proper maintenance could, and would, operate satisfactorily for years. Essentially, the system consists of a pump, typically mounted on the fire-wall, electrical switches, hydraulic cylinders mounted in pivoting frames with a large spring or springs, a closed loop of metal lines and rubber hoses, and a wiring harness. It powered the windows, the front seat and, on convertibles, the top.

The Achilles’ Heel of this system was the use of brake fluid as a medium. Since brake fluid starts attracting/ developing moisture the moment the bottle is opened, after years of inactivity it coagulates into a pasty, sometimes rock-hard consistency, clogging the lines and seizing up the pump and cylinders. This necessitates a rebuild of the pump and replacement of the cylinders; not an inexpensive proposition! This is why, in the owner’s manual, it’s stressed that all power equipment (seat, windows and top) be operated at least once monthly to “keep things flowing.”

Here are the principles of operation: the Hydro-lectric pump, comprising a motor resembling a starter, a housing containing two “rotors” in a cavity which pump the fluid, an electrical solenoid, and a reservoir at the bottom portion to hold the fluid, is mounted vertically on the firewall with three rubber “cushions.” Also mounted on the firewall, near the pump, is a circuit breaker to protect the wiring from overload or shorts in the circuit. A rubber hose (or two hoses if it’s a convertible) runs from the pump to a network of metal tubing and additional rubber hoses that go to the power seat, windows, and convertible top. Inside each door is a metal frame containing a hydraulic cylinder held in place with special clips, and either one or two very strong springs. The upper part of the frame has scissor-like arms which attach to the window channel. In each door pillar is a rubber hose which allows flex when the doors are opened and closed. On convertibles, two metal lines, with loops in them to allow for movement, are attached directly to the large cylinders that operate the top. One line goes into the top of each cylinder, the other to the bottom, so that the cylinder piston rod can either extend or retract, thereby raising or lowering the top.

A “gang” or master switch, containing four individual switches, is mounted on the driver’s side front door panel. This is used to control the four windows. When a window switch is pushed upwards, the circuit is completed, powering the motor on the pump, which then pumps fluid to the appropriate cylinder and raises the window. When the window switch is pushed downwards, an electrical solenoid at the bottom of the cylinder is activated, and a valve opens. The springs then gently, and quietly, pull the window down, forcing the fluid out of the cylinder, through the lines, and back to the pump reservoir. The power seat, which operates similarly, has its own switch.

HYDRO-LECTRIC MASTER (“GANG”) SWITCH AT DRIVER’S DOOR

On convertibles, an actuating rod with a knob labeled “power top” goes through the firewall and is attached to a Bakelite power top control valve. This is essentially an electrical switch and valve unit. When the power top rod is pushed in, or pulled out, the top portion of this unit rotates. Inside the unit is a spring which returns the rotating part to its “neutral” position, and circular copper strips. When the power top rod is pulled or pushed, the rotating portion will swivel, thereby completing the circuit and actuating the pump. As the top portion of the control valve is rotated, it also opens one of two ports, diverting the fluid either to the bottom part of the top cylinder, thereby raising the top, or to the upper part of the cylinder, lowering the top.

Sounds simple, doesn’t it? In the next installment, I’ll get into the more technical aspects of this system, such as the wiring of the switches, rebuilding the system, and troubleshooting techniques.